Optimisation Solution

For any model of wind turbine

Key Benefits:

2-4% increase to AEP • Reduction of critical loads above rated power

• Plug and Play integration for any model of wind turbine

2-4% increase to AEP • 20% reduction in critical loads above rated power • Plug and Play integration for any model of wind turbine

Optimisation Solution

The Windar Photonics Optimisation solution enables asset owners to increase annual energy production (AEP) by 2-4% and to decrease loads at high wind speeds by optimising the yawing of the wind turbine.

The Optimisation solution can be installed and integrated with the control system of any model of wind turbine and is delivered with the cyber-safe Nexus OS software platform.

The Windar Photonics Optimisation solution consists of:

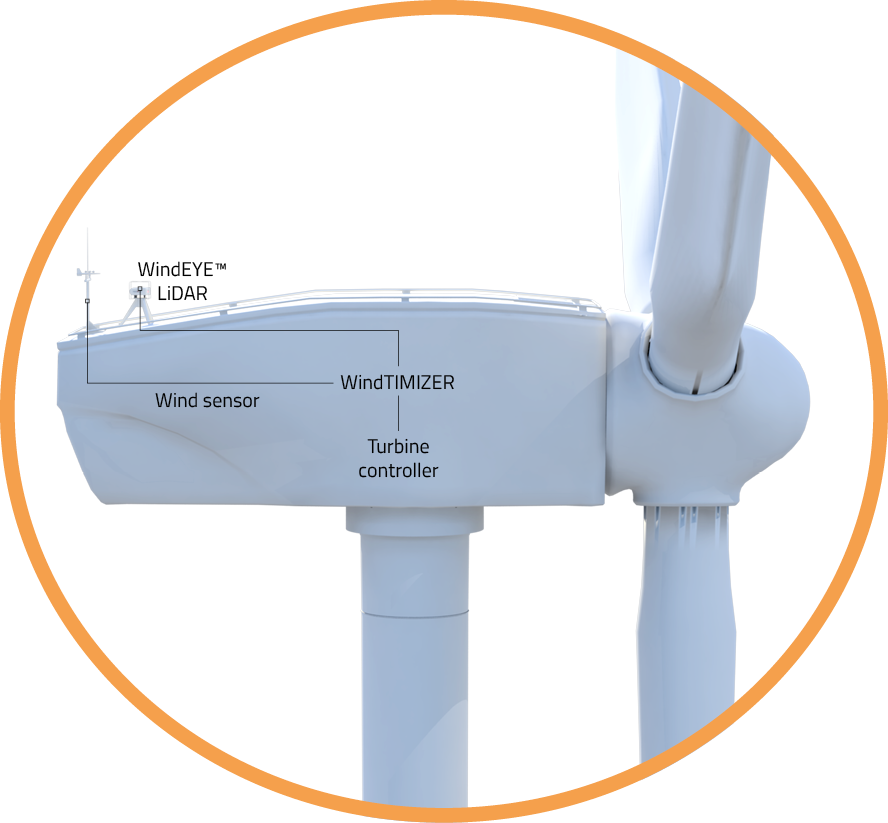

- The WindEYE LiDAR sensor

- The WindTIMIZER integration solution

- The Nexus OS software platform

WindEYE

LiDAR Sensor

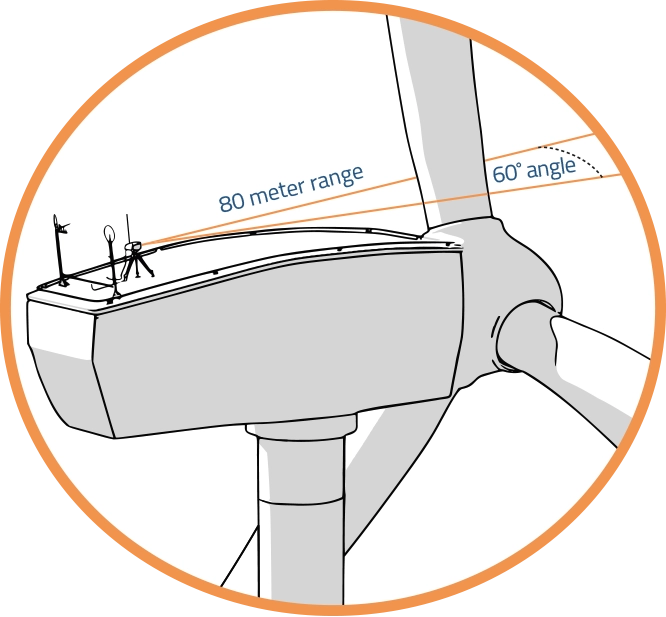

How the WindEYE LiDAR Works to Optimise Wind Turbine Performance

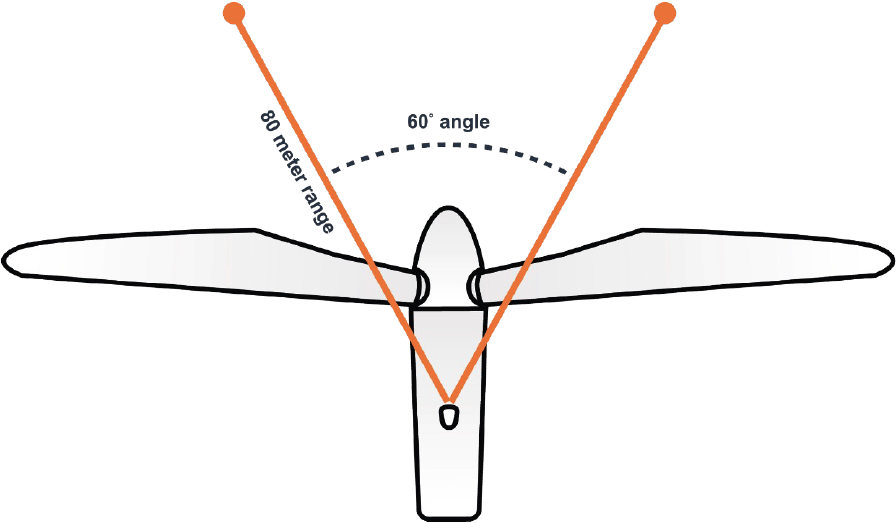

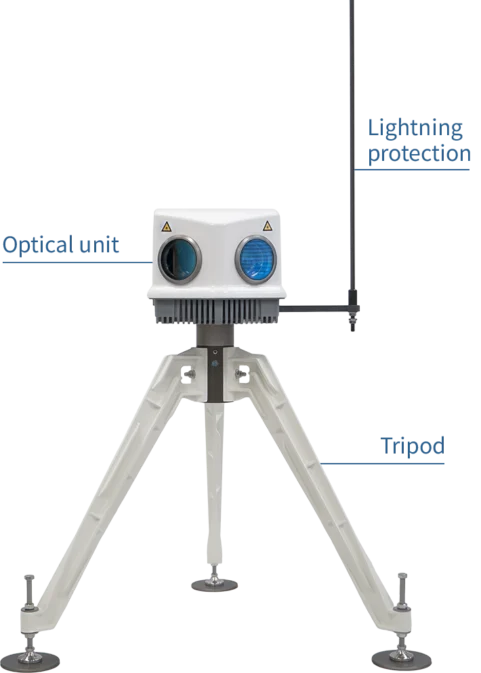

The WindEYE nacelle-mounted LiDAR sensor measures wind direction and wind speed up to 80 meters in front of a wind turbine, delivering accurate forward-looking wind data.

The WindEYE LiDAR integrates seamlessly with the wind turbine control system, enabling the turbine to receive precise wind information before it reaches the rotor.

By supplying the controller with this high-accuracy wind measurement, the WindEYE sensor combined with the WindTIMIZER integration can optimise yaw alignment, potentially increasing Annual Energy Production (AEP) by 2–4% and reducing turbine loads at high wind speeds on critical components.

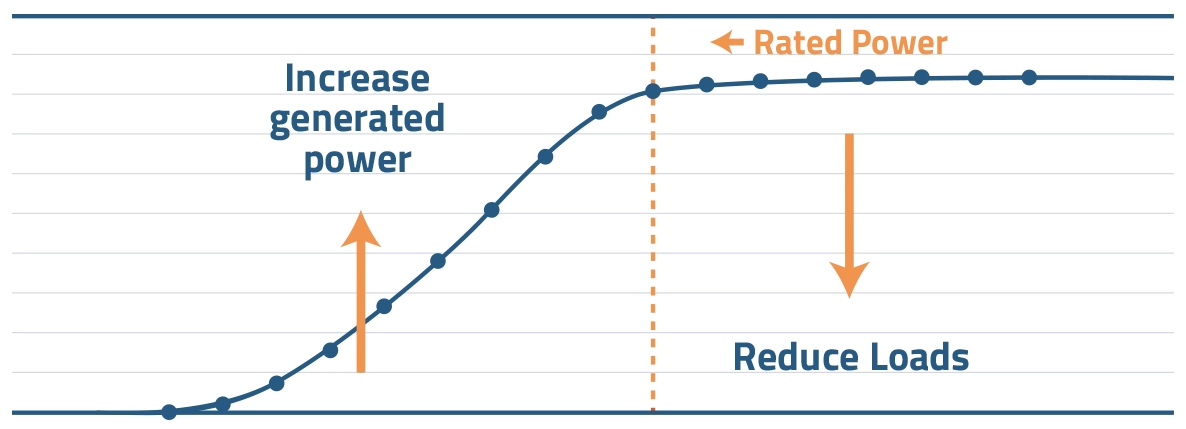

Increasing Energy Production and Reducing Loads with Yaw Optimisation Strategies

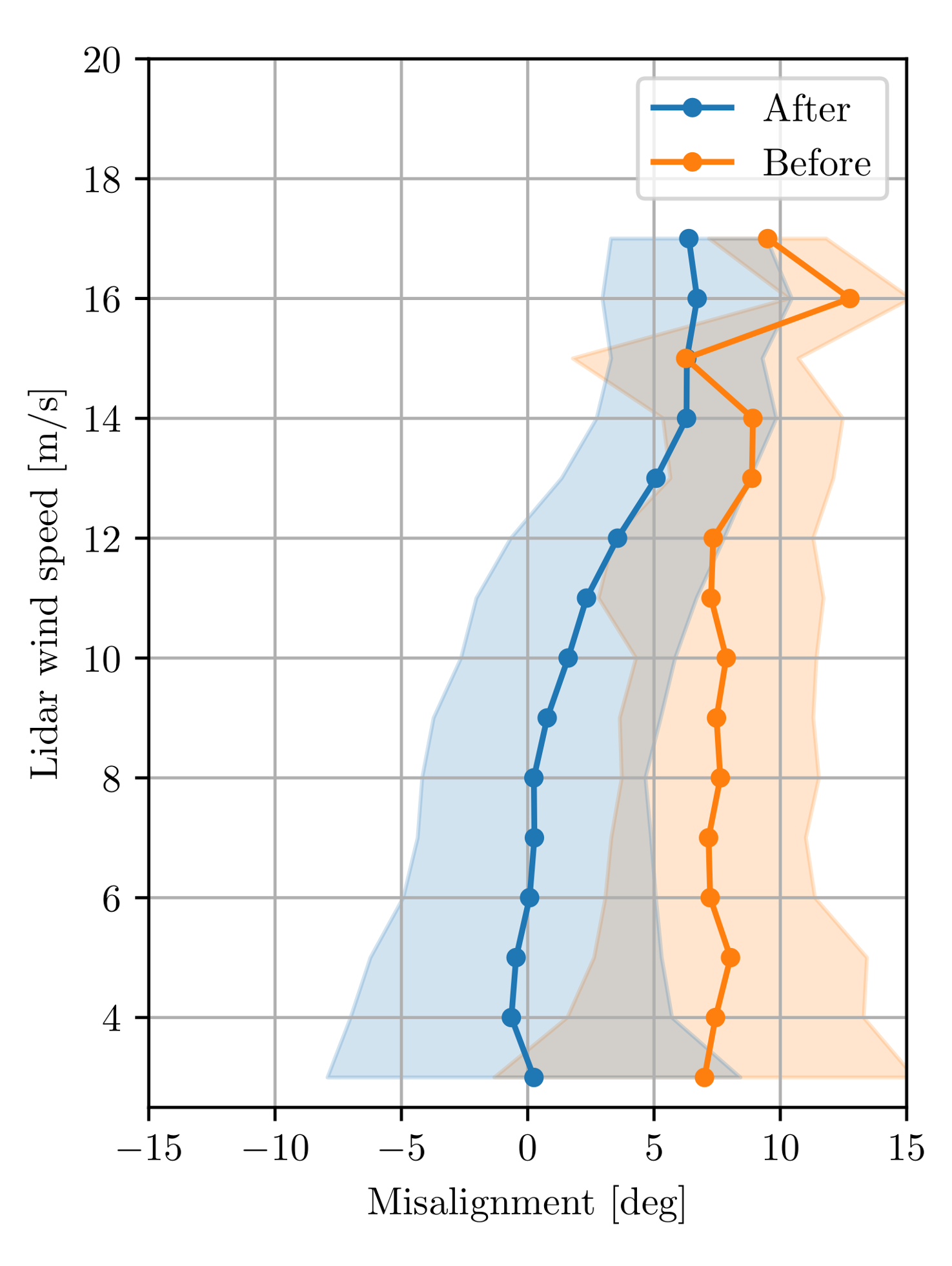

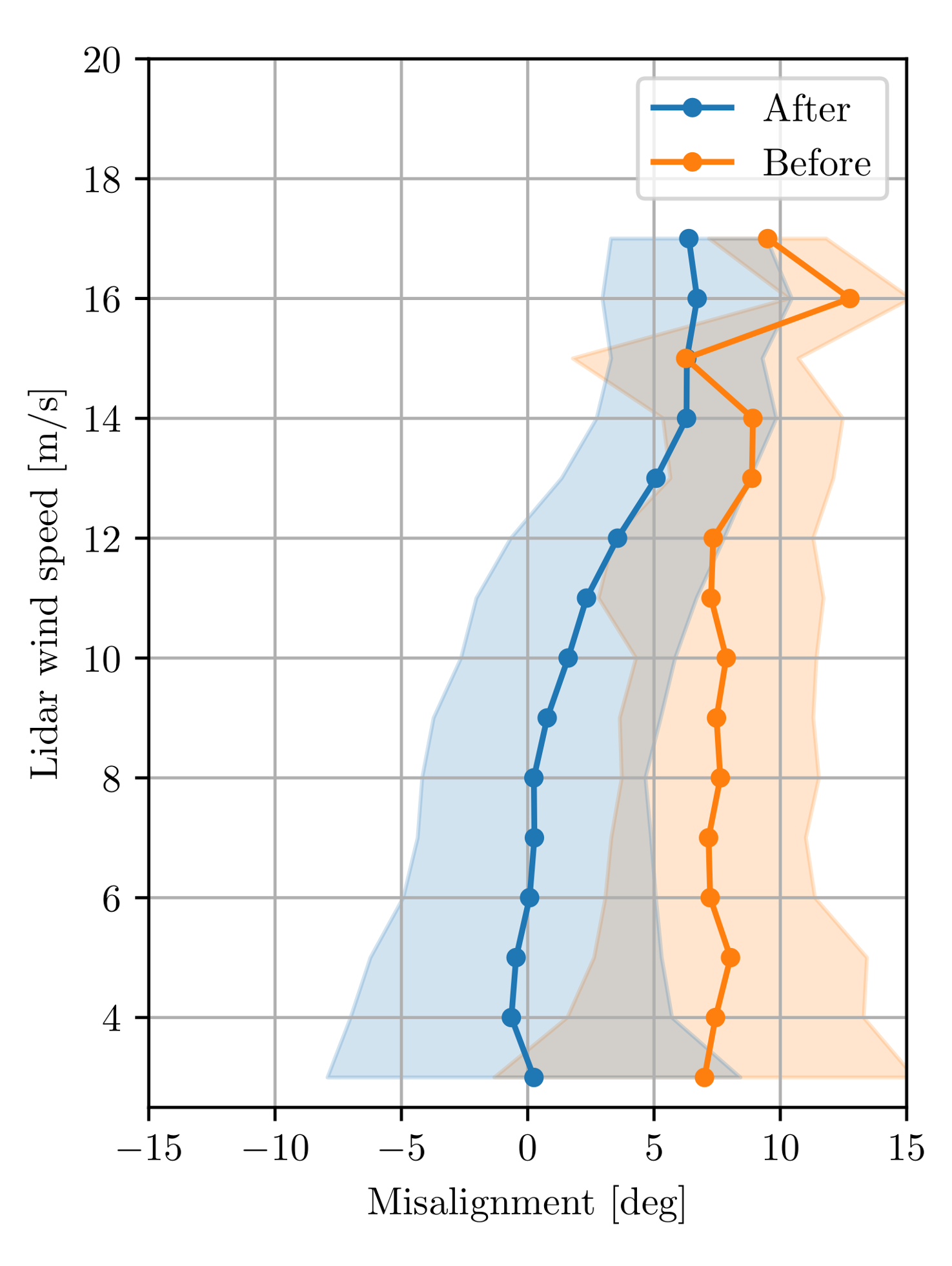

By correcting yaw misalignment on wind turbines, operators can achieve higher energy production below rated wind speed.

When the turbine is operating above rated power, the Windar Photonics optimisation solution introduces a controlled degree of misalignment. This strategy helps to reduce critical loads caused by high wind speeds – without sacrificing wind power output.

= >2.5% increase to AEP!

= >2.5% increase to AEP!

WindEYE LiDAR Technical Specifications

Continuous Wave Laser

Laser Source,

Eye safety class 4M

LiDAR system,

Eye safety class 1M

2 m/s – 75 m/s

1 Hz (2Hz optional)

-40°C to +55 °C

RS485, Ethernet

Optical Unit:

425mm x 300mm x 250mm

Tripod:

620mm ø 1000mm

Packed:

800mm x 400mm x 620mm

Optical Unit: 16kg

Tripod: 8kg

PSU (Power Supply): 9kg

Total, Packed: 42kg

Length: 10m. Diameter: 16.5mm

IP67

IP67

110 VAC / 230 VAC

12 Months

WindTIMIZER

Plug-and-Play LiDAR integration solution for any model of wind turbine

Control Integration

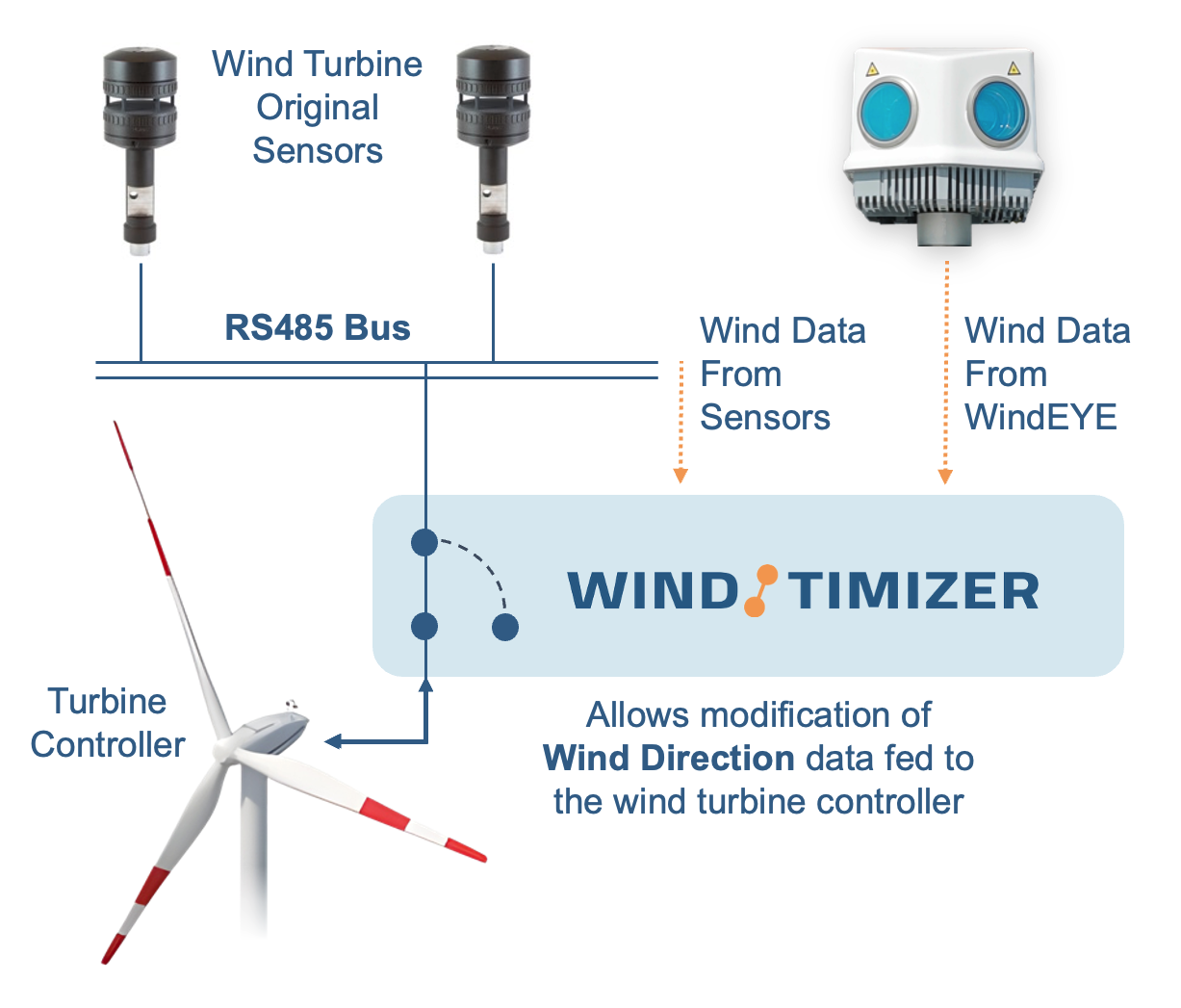

To activate the dynamic yaw optimisation feature of the WindEYE nacelle-mounted LiDAR sensor, the LiDAR must be integrated with the wind turbine control system. The WindTIMIZER is Windar Photonics’ plug-and-play retrofit solution, allowing the LiDAR sensor to connect seamlessly with both the turbine’s control system and its legacy anemometry.

How the WindTIMIZER Works

The WindTIMIZER receives signals from both the existing wind sensors and the WindEYE LiDAR system. It converts the WindEYE signals into the same protocol as the legacy wind-sensor signals and forwards this data to the turbine controller. This makes it possible to integrate the WindEYE without making any modifications to the control system itself.

NEXUS OS

Operating system for LiDAR Assisted Optimisation and Monitoring

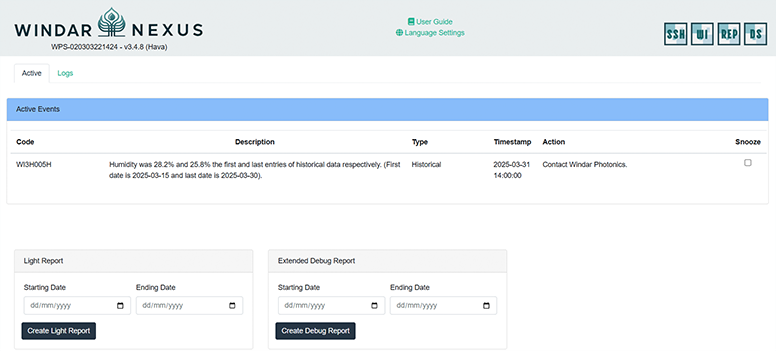

The NEXUS OS is an operating system for Windar Photonics’ LiDAR assisted solutions that offers groundbreaking advancements in wind turbine asset monitoring, enabling wind farm operators and asset owners to make informed, data-driven operations and maintenance decisions.

When the NEXUS OS is installed in conjunction with Windar Photonics’ LiDAR sensors, the platform enables operators to:

- Monitor entire wind turbine fleets with LiDAR sensors and collect data in one cyber-secure location.

- Optimise yaw alignment across the turbine fleet using WindTIMIZER integration technology.

- Generate on-demand and automated reports on turbine yaw alignment and performance.

- Ensure cyber-safe fleet and asset management with on-premises installation and no reliance on modems or remote data transfer.

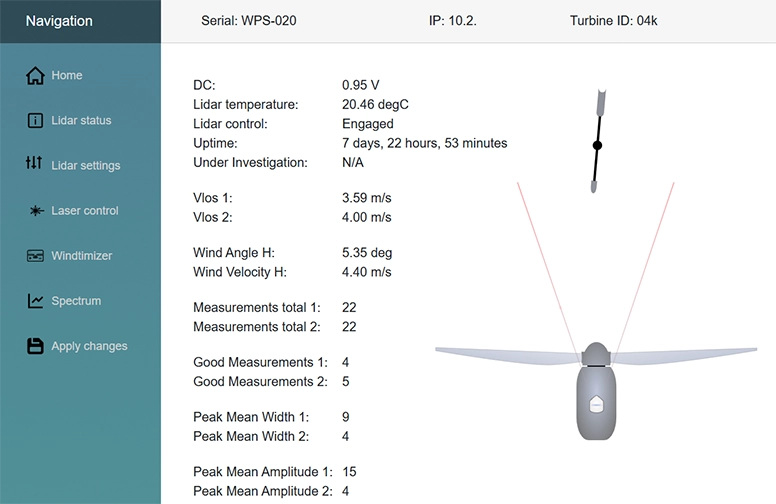

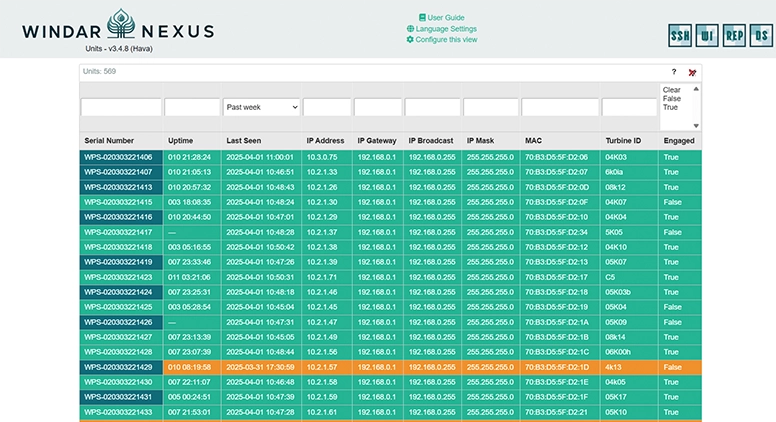

Easy-to-Use Graphical User Interface

All turbine-specific data is presented in an intuitive graphical interface, making it simple to navigate the different modules of the NEXUS OS and access detailed asset-specific information.

The main components of the NEXUS OS GUI include:

• A Control Center that lists every deployed unit

• An Event View section with detailed logs of events and flags

• The Li-App, a live monitoring application for individual LiDAR units

Cyber-Safe On-Premises Deployment

The NEXUS OS is deployed entirely on-premises, isolated from external networks. This allows operators to retain full control of servers and data traffic, while eliminating dependence on modems or service personnel. The result is automatic, cyber-safe monitoring and data handling

Future-Proof and Upgradeable Platform

The NEXUS OS is designed to be upgradeable and modular, allowing customers to add new software modules and features based on their specific wind turbine optimisation and monitoring needs.

Read more about the Windar Photonics Monitoring Solution here

Windar Photonics A/S - Baldersbækvej 24C, 2635 Ishøj - Denmark